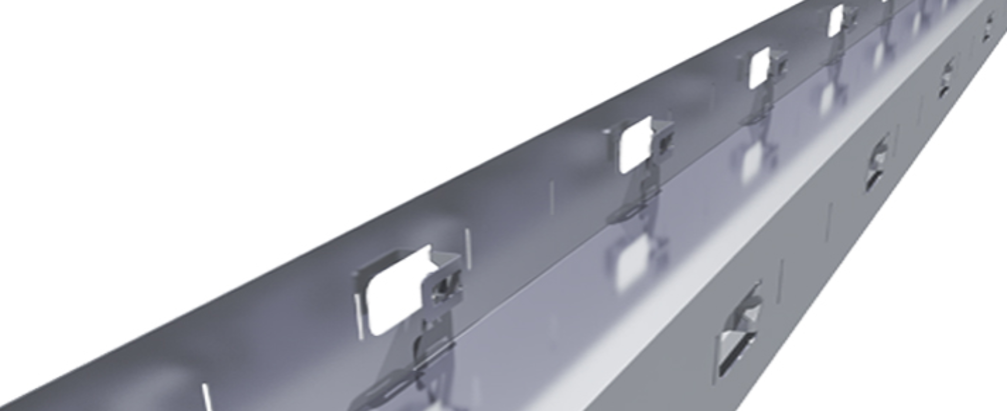

CLICK-WALL - Crunching Problems & Reduce the Risk of Errors

No Measuring

Typically about 20% of the time is used to measure where to place the racks. With CLICK-WALL there is no reason to measure anymore - saving time and reducing the risk of "measuring errors".

TIME SAVING, REMOVING POOR WORK POSITIONS, HIGH CONSISTENCY & QUALITY INCREASE!

No Fixture Tool

Typical the fixture tool is used 9 times for 1 m wall. This procedure is time consuming and despite fixtures can typically move under the mounting process. With CLICK-WALL no fixture tool is necessary and fixtures become more stable.

TIME SAVING & QUALITY INCREASE!

No bending Racks

When screwing the vertical steel studs, the webs of the studs bend at the top and bottom, consequently screws do not "bite" at these important positions. With CLICK-WALL the racks are fixed at these positions – consequently screws will ALWAYS bite.

SCREWS ALWAYS BITE!

Better Quality

The locking mechanism in the CLICK-WALL provides a better fixing and is significantly stronger than other known "quick mounting" solutions. Furthermore the system leaves little to coincidence and forces consistent quality

BETTER PRODUCT - LOWER TOTAL COST!

Higher Strength

By elongate the channel above doors to fit within modules it is possible to utilize a standard system where door and window openings can be clicked together. Result: Less steel is used and test and computer simulations shows an increased stiffness of 10%.

STRONGER FRAMES, ENABLE PRECISE ADJUSTMENT OF DOORS & WINDOWS!

Environment Efficient

Due to precise mounting - insulation effectiveness increase for heat and sound. The system also reduces the need for steel material around doors/ windows. All resulting in a smaller CO2 footprint.

SOLUTION ENVIRONMENTAL AND ECONOMICALLY ATTRACTIVE!